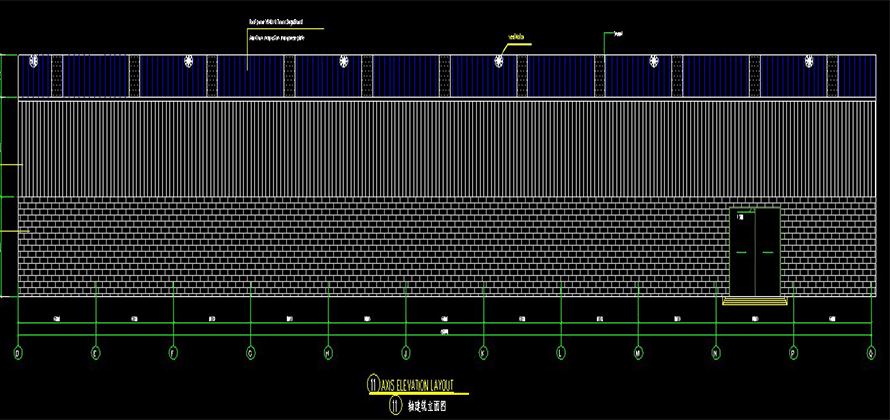

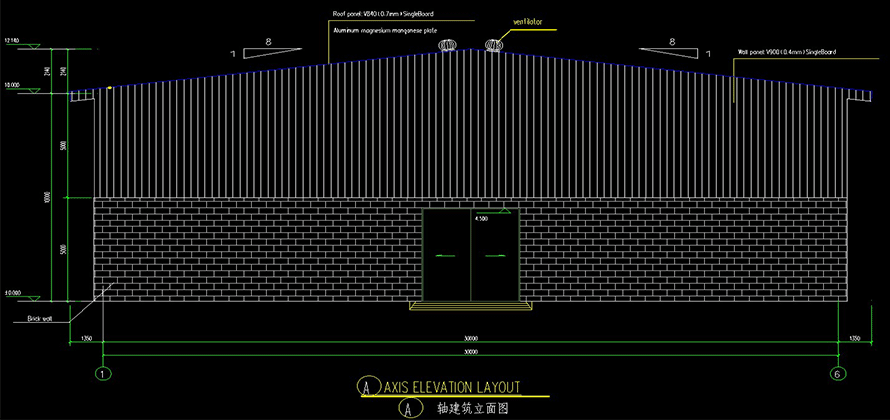

Sukat: 84mx60mx10m

Lugar: 5040sqm

Item No.:

gg-10-cmj-GPagbabayad:

T/T & L/CPinagmulan ng produkto:

Hebei, Chinadaungan ng pagpapadala:

TianjinLead Time:

about 30 daysPresyo:

30-50 usd/sqm|

Pangalan ng Produkto

|

Pagawaan ng bakal na bote ng tubig sa Ethiopia

|

|

Kolum at sinag

|

H beam na bakal

|

|

Purlin

|

C/Z seksyon na bakal

|

|

Materyal sa dingding at bubong

|

50/75/100/150mm EPS/PU/Rockwool/Fiberglass sandwich panel

|

|

Kumonekta

|

Ikonekta ang bolt

|

|

Bintana

|

PVC o aluminyo na haluang metal

|

|

Pinto

|

Electrica shutter door/sandwich panel door

|

Proseso ng paggawa ng istraktura ng bakal

Ang aming kumpanya ay na-optimize lamang ang linya ng produksyon ng produkto, pinagtibay ang mga advanced na makina ng produksyon, pinasimple ang proseso ng produksyon, pinahusay na kahusayan sa produksyon, at hindi kailanman maaantala ang panahon ng konstruksiyon sa ilalim ng kondisyon ng kalidad at dami.

1. Produksyon ng mga pangunahing bahagi ng bakal

Using automated equipment, the steel plate is cut into main steel components, with an error of ±2mm;

2. Production ofsmall piece

The automatic machine automatically aligns the plate for drilling, the deviation is less than or equal to 1mm, to ensure 100% installation without error

3. Assembling, submerged arc welding, straightening of section steel

Combine the three processes of assembly, submerged arc welding and correction to improve production efficiency, and the finished product error is ±2mm

4. All component numbers

All components are numbered, marked with numerical values and letters, which saves time for later production processes and improves production efficiency.

5. Cut the marked section steel

This step is to cut the marked section steel, using infrared scanning, the error range is within 2mm, the cutting edge is smooth and beautiful, which is convenient for later welding.

6. Assemble

Assemble all the connection boards and perform local spot welding with electric welding; check the dimensions to ensure that the dimensions of each component conform to the drawings.

7. Secondary welding

Weld all the connecting parts of the assembly process firmly, and cross the assembly process, with high productivity and fast welding efficiency.

8. Shot blasting and rust removal

Through the impact and cutting action of the spraying material on the profiled steel, the surface rust of the profiled steel is removed to increase the roughness, and artificial slag removal treatment is also performed, which makes a very good preparation for the spray painting, enhances the adhesion of the coating and the profiled steel, and prolongs the Durability of the coating film.

9. Spray paint

Spray paint according to the drawings and customer requirements, and spray 4 times. After the completion, the surface of the component will not sag, no bubbles, no cracks, and the color is uniform and beautiful.

10. Composite board veneer production

On average, each machine can produce 2,000 square meters a day; veneer production machines: we have 6 machines, which can produce 10,000 meters a day.

11.C section steel production

CNC C-shaped steel production machine, first punching, then bending, and then cutting, no burrs and no sticking, high production efficiency, can produce 5,000 meters a day.

12.Accessories production

FAQ

Nakaraang :

Tindahan ng bakal at gusali ng bodegaSusunod :

Proyekto ng bodega ng bakal na logistik ng SomaliaKung Interesado ka sa aming mga produkto at nais malaman ang higit pang mga detalye, mangyaring mag-iwan ng mensahe dito, tutugon ka namin sa lalong madaling panahon namin.

Mga kategorya

bagong produkto

Modernong prefabricated construction steel structure material warehouse. Magbasa pa

Malaking span weld h beam prefabricated steel structure workshop. Magbasa pa

Prefabricated light steel structure storage warehouse buildings. Magbasa pa

Dalawang-kuwento Ang manok ay na-export sa Pilipinas Magbasa pa

© Copyright: 2026 Hebei Baofeng Steel Structure CO.,LTD Lahat ng Karapatan ay Nakalaan.

IPv6 suportado ng network